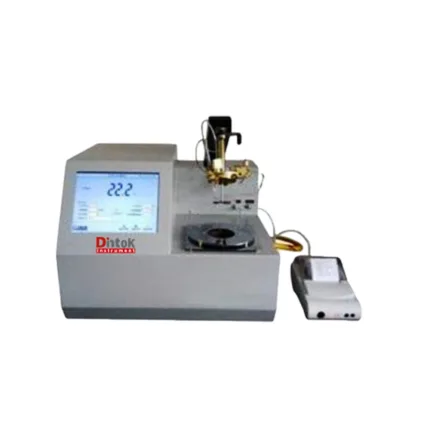

Automatic Pour Point Tester DPC-802

The instrument is in accordance with the standard ASTM D97 requirements of the design and manufacture of high-tech oil and related products, widely used in the petroleum industry and railway, aviation, electricity, related universities and research institutes.

Specification :

Technical characteristics

1. Embedded computer, imported industrial computer, 10.4-inch LCD touch screen, the entire Chinese operating system.

2. Using PPT imaging technology, computer automatic detection, analysis, to determine the pour point of oil samples.

3. Automatic completion of the sample lift, tilt, detection, automatic timing, automatically determine the test results, automatically save the test results; automatically complete the results of the whole process of printing.

4. With rapid detection function, according to the expected pour point directly set the lowest temperature of the cold bath, so that the sample quickly cooling, shorten the experimental time.

5. With functions of fault detection, analysis, judgment, and show on the display interface.

6. Imported glass temperature sensor, coefficient of thermal conductivity and the mercury glass thermometer consistent, the results more accurate.

7. Using metal cold bath, imported double compressor cascade refrigeration, cooling speed.

8. Double bath, double hole, bath temperature alone control, can simultaneously detect two sets of samples, sample in a bath to complete all the temperature points of the determination.

9. The instrument can be connected to the laboratory LIMS system and multi-machine networking.

Technical parameters and indicators

Determination of the minimum pour point: -56℃

Temperature control range: -69℃~+48℃

Bath temperature control accuracy: ±0.5℃

Cooling rate: From 48 ° C to -70 ° C ≤15 minutes

Bath temperature drop 17 ℃:≤150seconds

Outage time interval: >30min

Number of test holes: 2 holes

Power supply: AC(220±10%)V,(50±1)Hz

Power consumption: 1800W

Operational environment: Ambient temperature 5 ℃ ~ 40 ℃, relative humidity ≤ 85%

Dimensions: 700×550×640 mm(L×W×H)

Net weight: 106kg

Efficient, Standards-Compliant Pour Point Testing with the Automatic Pour Point Tester DPC-802

Ensure reliable low-temperature performance assessment of petroleum products with the Automatic Pour Point Tester DPC-802—a fully automated, microprocessor-controlled instrument designed for precise determination of the pour point of crude oils, lubricants, diesel, and fuel oils in accordance with ASTM D97, ISO 3016, IP 15, and GB/T 3535 standards. Ideal for refineries, quality control labs, and cold-climate fuel suppliers, the DPC-802 eliminates manual handling, improves repeatability, and enhances lab safety.

Engineered for Automation and Accuracy in Cold-Flow Testing

The DPC-802 Automatic Pour Point Tester uses a precision-cooled test chamber and motorized tilting mechanism to automatically monitor sample fluidity as it cools. At user-defined intervals, the system tilts the sample jar and uses optical or position sensors to detect movement—determining the lowest temperature at which the sample still flows. This hands-free approach ensures consistent results while reducing operator exposure to cold baths and hazardous samples.

- Full Compliance with ASTM D97 & ISO 3016 – Validated for petroleum and synthetic lubricants.

- Temperature Range: Ambient to –70°C – Covers extreme cold-flow requirements with ±0.5°C stability.

- Fully Automatic Operation – Auto-cooling, tilting, detection, and result calculation with minimal user input.

- Dual- or Multi-Sample Capability (Optional) – Test up to 2–6 samples sequentially or in parallel (model-dependent).

- Integrated Refrigeration System – No external coolant or dry ice required; eco-friendly refrigerant.

- Color Touchscreen & Data Logging – Stores 200+ test records with sample ID, method, and timestamp; USB export for reports.

Trusted for Fuel and Lubricant Quality Assurance

Pour point is a critical indicator of a fluid’s operability in cold environments—essential for aviation fuels, arctic-grade lubricants, and winter diesel. The DPC-802 ensures your products meet OEM and regulatory specifications while streamlining QC workflows. Its closed-system design minimizes solvent evaporation and operator contact with cold surfaces or hydrocarbons.

Whether you’re qualifying engine oils for northern climates or validating biodiesel cold-flow performance, the Automatic Pour Point Tester DPC-802 delivers fast, safe, and auditable results—every time.

Know your fluid’s limits. Guarantee performance in the cold.

Reviews

There are no reviews yet.