Explosion Proof Plug and Socket DXA & DXN

DXA

II2 G D Ex de IIC, Ex tb IIIC

Automatic IP66/IP67 water-and dust-tight

Integrated load-break switch

Lockable in connected or disconnected position with optional lockout shaft

Low temperature rating of -55°C

DXN

II2 G D Ex de IIC, Ex tb IIIC

Automatic IP66/IP67 water-and dust-tight

Integrated load-break switch

Robust and compact design

High performance GRP casing

specification :

MAIN FEATURES for DXA

Rated current (with wiring according to standard): 20 A

Ambient temperature: -55 °C to +60 °C

Maximum voltage: 550 V

Flexible wiring (min-max): 1-4 mm2

IP protection lid closed: IP66/IP67

Stranded wiring (min-max): 1,5-6 mm2

IP protection plug connected: IP66/IP67

ATEX zones: 1 & 2, 21 & 22

Shock resistance: IK10

Keying positions: 24

MAIN FEATURES for DXN

Rated current (with wiring according to standard): 20 A

Flexible wiring (min-max): 1-4 mm2

Maximum voltage: 550 V

Stranded wiring (min-max): 1,5-6 mm2

IP protection lid closed: IP66/IP67

Other wiring: on request

IP protection plug connected: IP66/IP67

Keying positions: 24

Shock resistance: IK08

Protection mode: de, tb

Ambient temperature: -40 °C to +60 °C

ATEX zones: 1 & 2, 21 & 22

Safe, Reliable Power Connections in Hazardous Areas: Explosion Proof Plug and Socket DXA & DXN

Ensure secure and compliant electrical connectivity in explosive environments with the Explosion Proof Plug and Socket DXA & DXN series—engineered for industrial settings where flammable gases, vapors, or combustible dust are present. Designed for use in oil & gas refineries, chemical plants, paint spray booths, mining operations, and grain handling facilities, these rugged connectors prevent ignition risks while delivering dependable power transmission.

Engineered for Safety and Durability

The DXA & DXN Explosion Proof Plug and Socket systems meet stringent international safety standards for hazardous locations, featuring flameproof (Ex d) enclosures that contain internal arcs or sparks and prevent them from igniting surrounding atmospheres. Available in multiple pole configurations (3P, 3P+N, 3P+N+E) and current ratings (16A to 125A), they support a wide range of industrial equipment—from lighting and motors to portable tools and control panels.

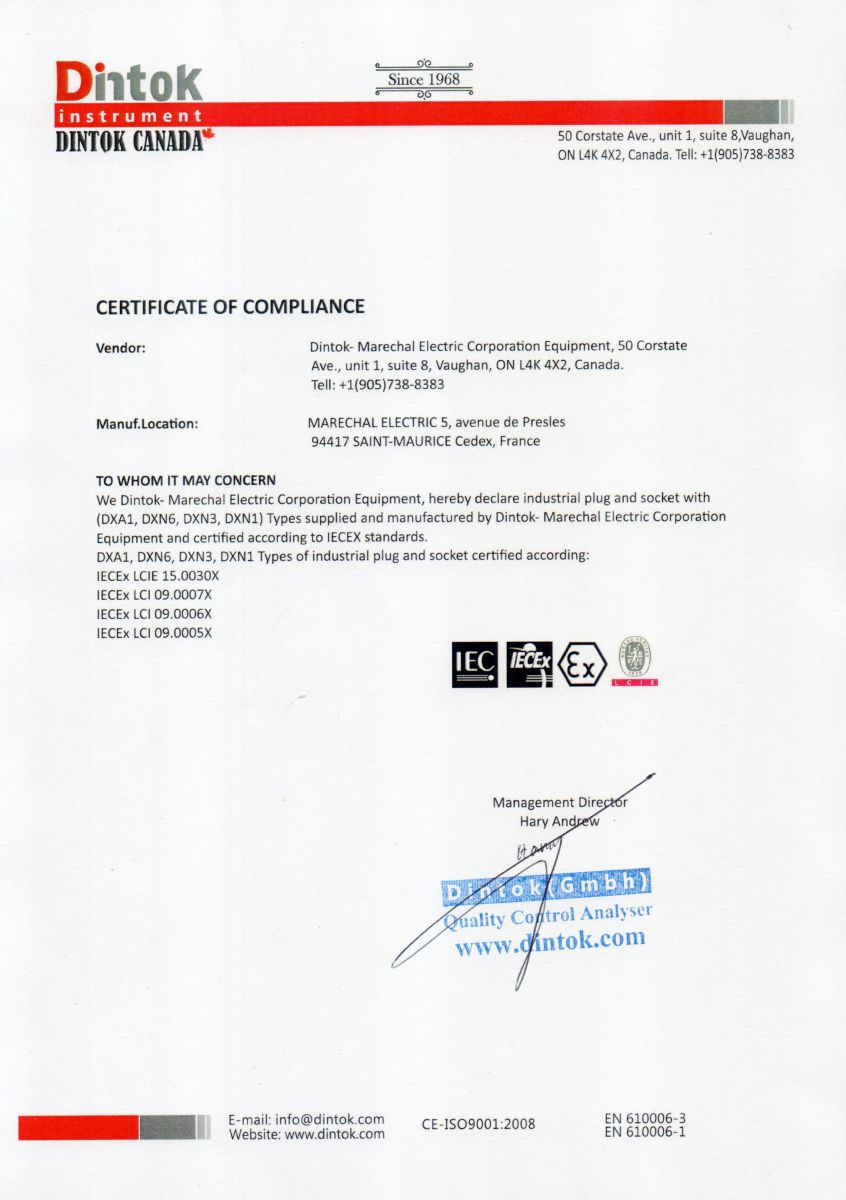

- Global Certifications – ATEX, IECEx, and NEC/CEC compliant for use in Zone 1/2 and Class I, II, III hazardous areas.

- Flameproof Cast-Aluminum Housing – Robust, corrosion-resistant enclosure with precise flame path design for explosion containment.

- IP66/IP67 Protection Rating – Fully sealed against dust, high-pressure water jets, and temporary immersion.

- Interlock & Keyed Designs – Prevents disconnection under load and ensures correct voltage/pin alignment.

- Wide Voltage & Frequency Range – Supports up to 690V AC, 50/60Hz for global deployment.

- Easy Installation & Maintenance – Cable glands integrated into design; clear labeling for quick identification.

Trusted Where Safety Is Non-Negotiable

Unlike standard electrical connectors, the DXA & DXN Explosion Proof Plug and Socket systems are rigorously tested to operate safely in the presence of explosive mixtures. Their ergonomic design allows for quick, tool-free mating—even with gloves—while maintaining a secure, vibration-resistant connection.

Whether powering temporary work lights in a refinery or connecting mobile equipment in a grain elevator, these connectors deliver peace of mind through certified safety and industrial-grade reliability.

Choose the gold standard for hazardous-area electrical connections—where every plug-in must be fail-safe.

Reviews

There are no reviews yet.