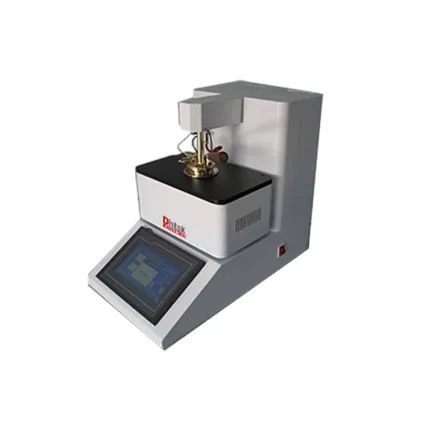

Grease Penetration Cone DGL1200

Grease cone penetration tester is made and desigend the standard of ASTM D217 Standard Test Methods for Cone Penetration of Lubricating Grease.

The sample is placed in a constant temperature bath at 25 ºC ±0.1 ºC, a standard cone with a load of 150 grams, moves vertically without obvious friction, sinks into grease or grease within 5 seconds, and the depth in Vaslin is called grease cone penetration to identify the soft hardness of grease.

Specification :

| Measurement range:(0~600)penetration scale |

Timing controller: 0s to 99s can be set. |

| Resolution: 0.01mm |

| Penetration accuracy: ±1penetration |

| Temperature control accuracy: 25±0.1ºC |

| Standard needle: 2.5±0.05g. |

| Standard cone: 102.5±0.05g. |

| Needle holder:It can be adjusted roughly and finely. Convenient to adjust and exact to aim the sample. |

Precision Tool for Lubricant Consistency Testing: Grease Penetration Cone DGL1200

Ensure accurate and standardized measurement of grease hardness with the Grease Penetration Cone DGL1200—a high-precision, calibrated cone assembly designed for use with cone penetration testers in accordance with ASTM D217, ISO 2137, and IP 50 standards. Engineered for lubricant manufacturers, quality control labs, and maintenance facilities, the DGL1200 is the essential consumable component that directly determines the reliability of grease consistency (NLGI grade) testing.

Engineered to Exact Metrological Specifications

The DGL1200 Grease Penetration Cone is precision-machined from polished stainless steel to meet strict dimensional and mass tolerances:

Cone angle: 9° ± 0.5°

Cone diameter at base: 32.7 mm ± 0.1 mm

Total mass (cone + shaft): 150 g ± 0.1 g

This exacting conformity ensures compatibility with standard penetration testers (e.g., DCP-701 series) and guarantees repeatable, comparable results across test batches and laboratories.

- Fully Compliant with ASTM D217 & ISO 2137 – Meets international standards for geometry and mass.

- High-Polish Stainless Steel Construction – Resists corrosion, easy to clean, and minimizes sample adhesion.

- Interchangeable Design – Quick-connect fitting for secure, wobble-free attachment to standard penetration rigs.

- Calibration Certificate Available – Traceable documentation for ISO 17025 and GMP compliance.

- Ideal for Worked & Unworked Grease Tests – Supports full NLGI grading (000 to 6) and mechanical stability assessment.

- Durable Storage Case Included – Protects cone from damage and contamination between uses.

Trusted for Lubricant Quality and Performance Validation

The penetration value—measured in 0.1 mm increments—directly defines a grease’s NLGI grade and its suitability for specific applications (e.g., high-speed bearings vs. chassis lubrication). Using a non-compliant or worn cone introduces significant error, leading to incorrect grading and potential field failures. The DGL1200 ensures your penetration tester delivers trustworthy data every time.

Whether you’re formulating a new lithium-complex grease or verifying in-service lubricant degradation, the Grease Penetration Cone DGL1200 is the critical link between your instrument and accurate, standards-compliant results.

Precision starts at the tip. Trust your measurements with a cone built to standard.

Reviews

There are no reviews yet.