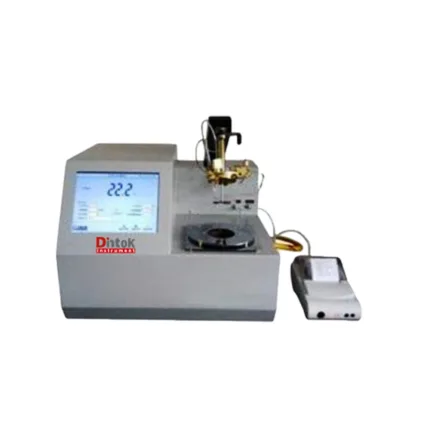

Pour and Cloud Point Tester DPC1015

DPC1015 Solidifying, pour, cloud & cold filter plugging point tester conforms to ASTM D97 standard. It is used to test the solidifying, pour, cloud and cold filter plugging point of petroleum products. Four functions includes in one machine.

Specification :

Features

1.Professional refrigeration, import dual compressors cooling, cooling rate is fast and stable.

2.The instrument is made of stainless steel bath, anti-corrosion, two slots and four holes, can proceed four experiments within one machine.

3.Digital display temperature control, high precision, digital timer alarm, easy to adjust.

4.Using split structure, to avoid cold source compressor working vibration impacting the testing results.

5.Instrument got reasonable structure, beautiful shape, easy operation.

Technical parameters:

Constant temperature bath

Rated voltage: AC 220V±10% 50Hz

Slot power: 350W×2(700W)

Slot holes: Two slots and four holes

Bath volume: 5L

Temperature control: Digital display temperature control

Temperature range: Room temperature ~ -68°C

Temperature accuracy: ± 0.1°C

Temperature sensor: Pt100 (Platinum resistor)

Timer: Two timer devices

Mixing method: Mixing motor, 1200r/min

Ambient requirement temperature: 15~30°C Humidity≤85%

Special cold source:

Rated voltage: AC 220V±10% 50Hz

Input power: 800W

Cooling time: 100min (Room temperature≤30°C)

Downtime: duration ≥20min

Ambient temperature requirement: 15~30°C Humidity≤85%

Efficient Low-Temperature Performance Testing with the Pour and Cloud Point Tester DPC1015

Streamline cold-flow characterization of fuels and lubricants with the Pour and Cloud Point Tester DPC1015—a compact, semi-automatic instrument engineered to determine both cloud point and pour point in full compliance with ASTM D2500 / D5773 (cloud) and ASTM D97 / D5949 (pour), as well as ISO 3015, ISO 3016, ISO 3019, and IP 15 / IP 374 standards. Designed for fuel terminals, lubricant blenders, and field laboratories, the DPC1015 delivers reliable low-temperature assessment to ensure operability in cold climates.

Engineered for Practical, Standards-Based Cold Testing

The DPC1015 Pour and Cloud Point Tester features a single refrigerated test chamber capable of cooling samples down to –70°C, with a user-friendly interface for switching between cloud and pour point modes. For cloud point, the operator visually observes the sample through a magnified window with LED backlighting to detect the first wax crystal formation. For pour point, the unit includes a manual tilting mechanism to check fluidity at 3°C intervals, following standard procedural guidelines.

- Dual-Function in One Compact Unit – Perform both cloud and pour point tests without changing hardware.

- Compliant with ASTM & ISO Methods – Supports both manual (D97/D2500) and semi-automatic (D5949/D5773) protocols.

- Temperature Range: Ambient to –70°C – Covers arctic-grade diesel, jet fuel, and industrial lubricants.

- Precision Cooling System – Thermoelectric (Peltier) or compressor-based cooling with ±0.5°C stability.

- Clear Observation Window with LED Lighting – Enhances visibility of wax formation and sample movement.

- Digital Temperature Display & Timer – Built-in stopwatch and real-time temp readout for accurate manual testing.

Trusted for Fuel Quality and Winter Readiness

Cloud point indicates the temperature at which wax crystals begin to form—critical for diesel and biodiesel operability—while pour point defines the lowest temperature at which oil remains pumpable. The DPC1015 helps ensure your products meet EN 590, ASTM D975, and OEM winter-grade specifications, preventing filter clogging, gelling, or equipment failure in cold environments.

Ideal for routine QC in distribution terminals, blending facilities, or maintenance depots, the Pour and Cloud Point Tester DPC1015 offers a cost-effective, reliable solution for labs that value operator involvement and method transparency.

Know your cold limits. Guarantee winter performance. Stay compliant.

Reviews

There are no reviews yet.