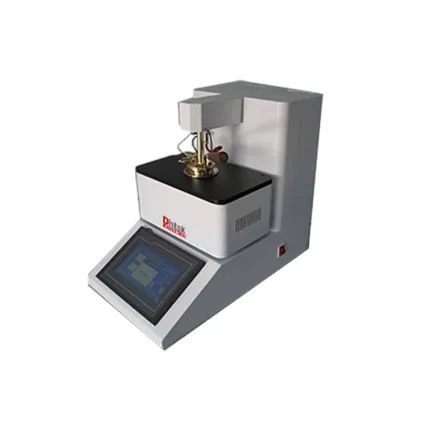

Semi-Automatic Pensky-Martens Closed-Cup Flash Point Tester DSP2003B

DSP2003B Closed-cup flash point tester for petroleum products Pensky-Martin method) (semi-automatic model)is suitable to the standards of GB/T261 & ASTM D93. It is used to test the flash point of fuel oil and lubricating oil and so on under under experimental condition.

Specification :

1. The upper cover is equipped with a standard fireball comparer, easy to operate.

2. Heating with stepless voltage regulator, heating-rate equability.

3. Stainless steel heater, safe and reliable.

4. Electrical motor to agitate oil sample makes the temperature of oil sample up equability.

5. Remote control to light fire could improve the accuracy in test.

6. The instrument is designed rationally, has attractive appearance and easy to operate.

Reliable, Operator-Guided Flash Point Testing with the Semi-Automatic Pensky-Martens Closed-Cup Flash Point Tester DSP2003B

Achieve accurate and standards-compliant flash point determination for viscous or high-flash petroleum products with the Semi-Automatic Pensky-Martens Closed-Cup Flash Point Tester DSP2003B—a robust, user-controlled instrument designed for laboratories requiring precision without full automation. Compliant with ASTM D93, ISO 2719, IP 34, and GB/T 261, the DSP2003B is ideal for testing diesel, lubricating oils, residual fuels, and bitumen where manual oversight ensures optimal test integrity.

Engineered for Controlled, Standards-Based Operation

The DSP2003B Semi-Automatic Pensky-Martens Flash Point Tester features a precision electric heating system with digital temperature control and a manual ignition mechanism using a small gas flame or built-in electric igniter. The operator initiates ignition trials at defined temperature intervals while the instrument maintains a stable heating rate per method requirements. A clear viewing window and adjustable flame allow visual detection of the flash point, ensuring alignment with traditional test protocols.

- Compliant with ASTM D93 & ISO 2719 – Validated for high-flash, viscous, and contaminated petroleum products.

- Temperature Range: Ambient to 400°C – Suitable for heavy fuels and lubricants with high flash points.

- Semi-Automatic Operation – Automatic heating and temperature monitoring; manual ignition and flash observation for method fidelity.

- Digital PID Temperature Controller (±0.5°C) – Ensures consistent ramp rates and test repeatability.

- Adjustable Test Flame & Safety Shield – Precise flame size control with protective barrier for safe viewing.

- Compact Benchtop Design with Fume Compatibility – Easily integrated into ventilated lab environments.

Trusted for Hands-On Quality Control and Certification

The Pensky-Martens method remains the global standard for flash point testing of non-volatile petroleum liquids. The DSP2003B offers an ideal balance for labs that value operator involvement—such as training facilities, small refineries, or inspection agencies—while still delivering repeatable, auditable results. It supports compliance with OSHA, DOT, and GHS classification requirements and is widely accepted for custody transfer and product certification.

Whether you’re verifying marine fuel safety or qualifying industrial lubricants, the Semi-Automatic Pensky-Martens Closed-Cup Flash Point Tester DSP2003B provides dependable, method-accurate performance with operator control at its core.

Precision you guide. Compliance you trust.

Reviews

There are no reviews yet.