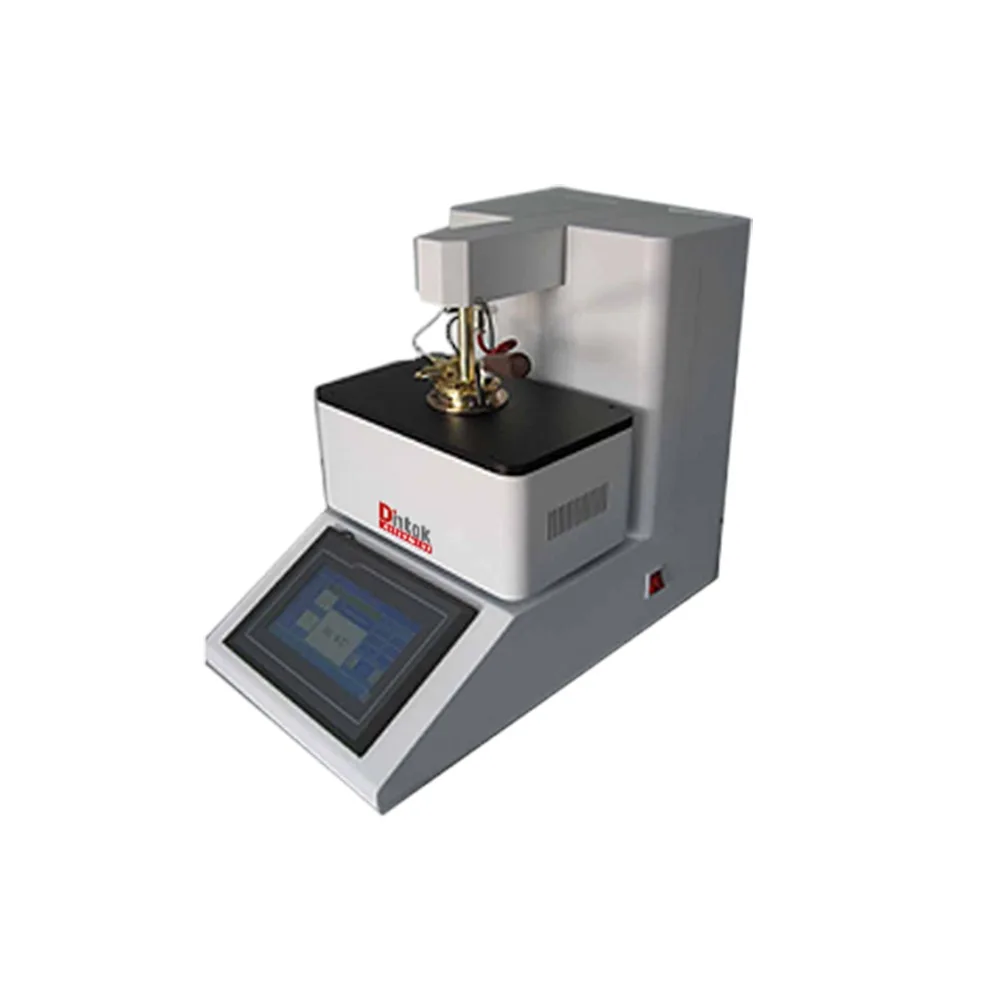

Automatic Pensky-Martens Closed Cup Flash Point Tester DAP-2612

DAP-2612 Automatic Pensky-Martens Closed Cup Flash Point Tester conforms to ASTM D93 Standard Test Methods for Flash Point by Pensky-Martens Closed Cup Tester. It is used to test for those liquids which have a kinematic viscosity of 5.8mm 2/s (cSt) or more at 37.8℃ or 9.5mm 2/s (cSt) or more at 25℃ (77℉), or that contain suspended solids, or have a tendency to form a surface film while under test. Other classification flash points have been estabilished by these departments for liquids using these test methods.

ُpecification :

Features

1.Touch screen control, it can connect to the computer

2.Indenpendent heating module with monitoring interface, it follows the standard requirement to heat 3.Automatic ignition,flash point detecting alarm, calculate, print, record and air cooling

3.Standard reagent calibration:According to the standard, there are procedure A and procedure B

Technical Parameters

1.Rated voltage: AC220V±10% 50Hz

2.Power: 700WScreen: 4 wires resistor touch screen

3.Ignition: Gas ignition

4.Printing method: Thermo printer

5.Repetitive error: ±1℃

6.Ambient requirement: Temperature: 10~40℃; Humidity≤85%

Fully Automated Flash Point Testing with the Automatic Pensky-Martens Closed Cup Flash Point Tester DAP-2612

Ensure safety, compliance, and efficiency in flammable liquid testing with the Automatic Pensky-Martens Closed Cup Flash Point Tester DAP-2612—a high-performance, microprocessor-controlled instrument engineered for precise determination of flash point in fuel oils, lubricants, bitumen, and viscous petroleum products in full compliance with ASTM D93, ISO 2719, IP 34, GB/T 261, and DIN 51758 standards. Designed for refineries, certification labs, and industrial quality control, the DAP-2612 delivers fully automated, flameless, and operator-independent results—even for difficult-to-test samples.

Engineered for Precision, Safety, and Throughput

The DAP-2612 Automatic Pensky-Martens Flash Point Tester uses an advanced electronic ignition system (no open flame) and a sealed test chamber to safely heat samples from ambient to 400°C while continuously monitoring for flash events via a highly sensitive ionization or optical detection sensor. The instrument automatically controls heating rate, performs ignition trials at defined intervals, detects the flash point with ±0.5°C accuracy, and initiates rapid cooling—minimizing cycle time and eliminating human error.

- Full Compliance with ASTM D93 (Pensky-Martens) & ISO 2719 – Validated for diesel, residual fuels, lubricants, and bitumen.

- Flameless Electronic Ignition – Enhances lab safety; no gas cylinders or open flames required.

- Wide Range: Ambient to 400°C – Handles high-flash, viscous, and contaminated samples.

- Automatic Operation from Start to Finish – Auto-heating, ignition, flash detection, cooling, and result reporting.

- Integrated Forced-Air Cooling System – Reduces test cycle time by up to 50% between runs.

- Color Touchscreen & Data Management – Stores 200+ test records; USB export to CSV; supports sample ID and method tracking.

Trusted for Regulatory and Industrial Fuel Testing

Flash point is a critical safety parameter for transportation, storage, and handling under OSHA, DOT, REACH, and GHS regulations. The DAP-2612 ensures your products meet global specifications while supporting internal quality benchmarks for heavy fuels, used oils, and polymer-modified materials. Its closed-system design prevents vapor release and protects operators from exposure to hazardous fumes.

Whether you’re certifying marine fuel oil or validating in-service lubricant safety, the Automatic Pensky-Martens Closed Cup Flash Point Tester DAP-2612 delivers laboratory-grade reliability—automatically, safely, and efficiently.

Automate compliance. Eliminate risk. Trust every result.

Reviews

There are no reviews yet.